|

UNION Hydraulic Shears

-FOR THE CLEANEST CUTS AND LONGEST BLADE LIFE

AT THE BEST COST

-High Performance, High Value, Precise Control

Information

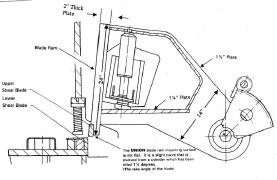

The UNION hydraulic shears feature a direct, twin cylinder

swing beam design which is the most power-efficient design possible.

Since guides and slide ways are eliminated, far less horsepower

is required. Guillotine type shears use end-mounted guides and

slide ways for ram guiding and have relatively little lateral

support in the middle of the ram. Consequently, under load, the

clearance gap in the centre of the cut becomes wider than at the

ends, resulting in poor quality cuts and shortened blade life.

The UNION swing beam design has massive lateral support to eliminate

sideways deflection at the centre of the cut. Even the smallest

UNION shears have a massive 1 1/4" x 24" lateral support plate

placed at a 90 degree angle to the 2" thick x 24" deep ram.

Because the UNION blade ram is part of the swing beam and

because its pivot point is at table height on the side frames

above the table. Thus, all models feature a generous throat depth

that is not possible with conventional slideway machines without

massively increasing the size of frame members.

UNION Hydraulic Shears are designed and constructed to

provide high-speed shearing of blanks with clean, square edges,

and to exacting working tolerances.

All UNION Hydraulic Shears feature the swing beam design

ensuring consistently accurate parts while providing smooth, quiet

operation. These cost efficient, quality shears are available

in capacities from 1/4" - 3/4" (6mm-20mm) and 98" - 194" (2m-5m)

cutting length. Unitized box construction provides for maximum

rigidity and strength.

This simple design with swing beam upper blade, strong

rigid frames, and constant minimum rake angle assures that the

sheared blanks are precisely cut with a minimum of bow twist or

camber.

UNION Hydraulic Plate Shears are equipped with the productive

features and safety devices for optimum, accurate shearing performance

found on more expensive units. Feature for feature, UNION Hydraulic

Shears are a smart, economical choice for plate shearing.

SWING BEAM DESIGN

The beam holding the upper knife pivots on large spherical

roller bearings, while hydraulic cylinders mounted into the side

frames generate the cutting pressure at the end of each cutting

stroke, the hydraulic pressure is released and return cyliinders

move the beam to the top of stroke, the back gauge design and

its interconnection with the swing beam gives immediate clearance

to the sheared material, allowing it to drop away without jamming

the lower blade and back gauge. Less maintenance is required with

the swing beam design, since guides and slideways are eliminated.

RUGGED CONSTRUCTION

Stress-relieved, unitized box construction of the table

and extra thick, rolled steel frames provide maximum resistance

to deflection and torsional force. Increased throat depth in the

side frames allows for progressive slitting of strips longer than

the blades. Due to swing beam design, there is no deflection at

the throat area of the shear.

MINIMUM RAKE ANGLE

Due to strong, rigid construction, swing beam design and

powerful hydraulics, hydraulic shears feature a constant minimum

rake angle for consistent, quality shearing, at full capacity,

with the least amount of distortion.

BLADE GAP ADJUSTMENT

A conveniently located adjustment lever enables the operator

to accurately adjust the blade clearance on both sides of the

machine simultaneously. Optional motorized adjustment is available.

PRESSURE SENSING HOLD DOWNS

Hydraulic hold downs are synchronized with the upper blade,

travel to provide maximum hold down pressure at the moment of

shearing, thus assuring cutting accuracy. As shearing forces on

the plate increases, the hold down pressure increases proportionately.

The hold down feet can hold two or more plates of different thicknesses

for simultaneous shearing on the same stroke. At one end of the

shear, two hold downs are mounted close together for ease in cutting

narrow strips.

SQUARING ARM

All shears are equipped with a heavy-duty squaring arm

which is mounted at precisely 90 degrees to the shear blades.

The squaring arm has a recessed stainless steel rule in inch/metric.

The shear is also equipped with ball transfers to facilitate even

the heaviest jobs.

MODERN BLOCK HYDRAULICS

The hydraulic system is comprised of long life, heavy-duty

components mounted on a common block. Tubes and connections are

minimized, and access and serviceability are made easy. The plunger

pump is quiet and extremely reliable. The large capacity oil reservoir

eliminates the need for oil cooler. A factory preset relief valve

prevents overloading mechanical parts and hydraulic circuit.

ELECTRONIC STROKE ADJUSTMENT

For faster stroke rates, the operator can quickly adjust

the stroke length to suit the job. Smaller blanks require less

stroke length, thus providing faster cycling of the beam.

OPERATOR CONTROL CONSOLE

The control console is conveniently located on the front

of the shear for easy accessibility. The control includes a back

gauge mechanical readout, in .001" increments, and a stroke counter.

FRONT-CONTROLLED POWER BACK GAUGE

The standard heavy duty, motorized back gauge is front

operated and adjusted through the operator's control console.

The precision back gauge is two position - "down" for positioning

and shearing and "up" for clearance. The gauge stop, automatic

"retreat" position allows for shearing peices longer than the

extended range of the back gauge.

HINGED INTER-LOCKED BARRIER GUARDS

The UNION Shear has a unique inter-locked barrier guard.

This allows the operator to safely pickup one side of the guard

in order to work short pieces. Lifting the guard disconnects power

to the foot pedal. The shear will not operate until the guard

is lowered into the down position.

SHADOW LIGHTING

For fast, visual positioning of sheets with scribed lines

or punched marks, an intense light is provided. The light source

casts a precise shadow line for accurate positioning and shearing.

HYDRAULIC CYLINDERS

The separate, nitrogen-filled, return cylinders are mounted

below the hydraulic cylinders. The return cylinders, independent

from the hydraulic cylinders, automatically retract the blade

to the top of stroke position during power shut down, emergency,

or after the cutting stroke is completed. They also act as counterbalance

to the shear.

BLADE CLEARANCE ADJUSTMENT

Proper blade clearance can be adjusted easy to assure clean,

square edges on every part.

QUALITY BLADES

Shears are equipped with high carbon, high chrome blades.

Standard Features

·Front controlled motorized retractable back gauge with digital

readout

·Heavy duty squaring arms with stainless steel scales and disappearing

stops

·Electronic stroke length adjustment

·Generous throat depth for shearing to unlimited length

·Triple row ball transfers on table

·Piano wire shadow line gauging

·Urethane removable anti-marring feet for hold downs

·Automatic counter control

·Multi-position precision blade clearance adjustment

·Precise, front-controlled, motorized, retractable backgauge with

precision

mechanical readout

·Electronic stroke adjustment

·Stroke counter

·Ball transfers

·Emergency stop

·Lockable power control

·Heavy duty 40" squaring arm and stainless steel scale

·Guards for operator protection

·Full length shadow light

·Modern block and cartridge hydraulics

·Electrical system 220/380/440/575 volts, 60/50 hz

·Complete hydraulic, electrical and frame overload protection

·Oversized hydraulic cylinders

·Low rake angle to reduce distortion

Options

·CNC gauging for front and/or back gauge

·LED readout

Plate Shear Specifications

(Please see this text file

for detailed specifications)

|